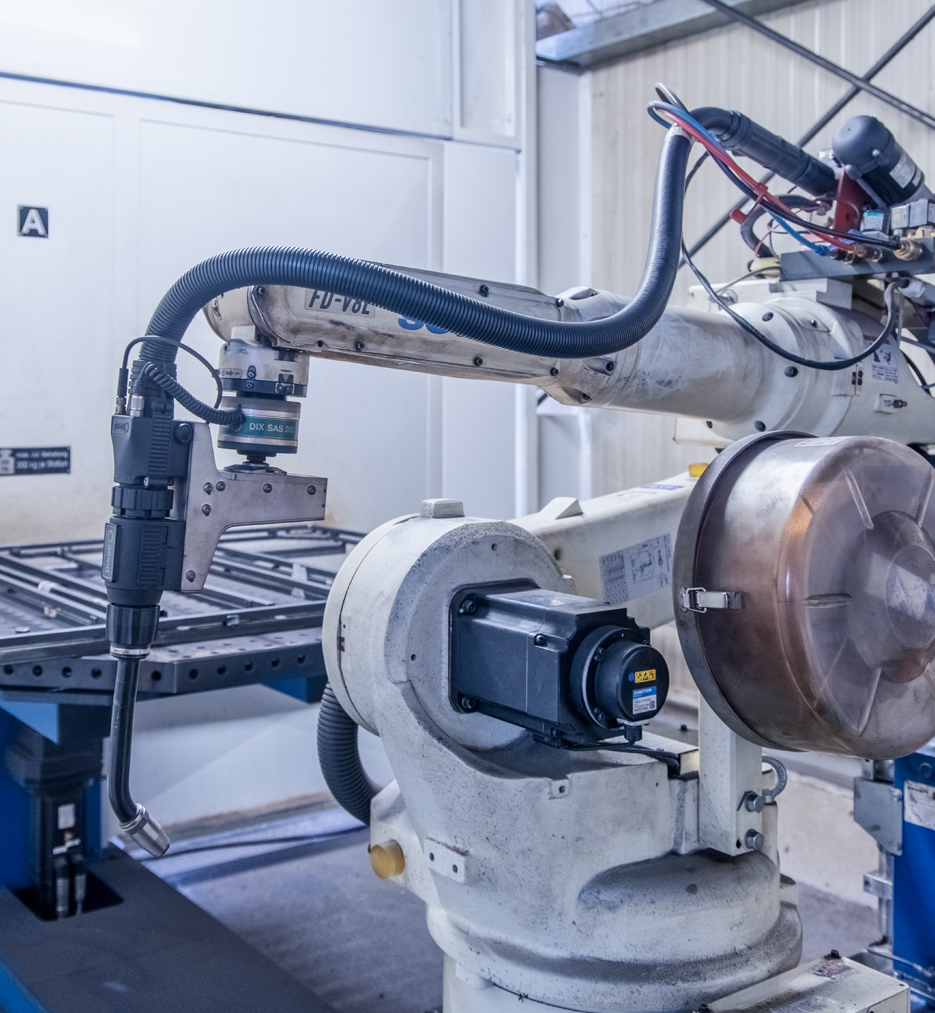

CNC Welding Robot

Our CNC welding robot enables highly precise, repeatable weld seams – even with complex geometries and large production volumes. Through automated motion sequences and programmable welding parameters, we achieve consistent quality, shorter production times, and optimal material utilization. Ideal for series production and components where dimensional accuracy and repeatability are critical.

CNC Milling

With our CNC milling machines, we manufacture precision components made of steel, stainless steel, and aluminum – from individual parts to series production. By using advanced control technology, we achieve tight tolerances, clean surface finishes, and high repeatability. Complex shapes and precisely fitting contours are produced efficiently and cost-effectively – exactly according to your technical specifications.

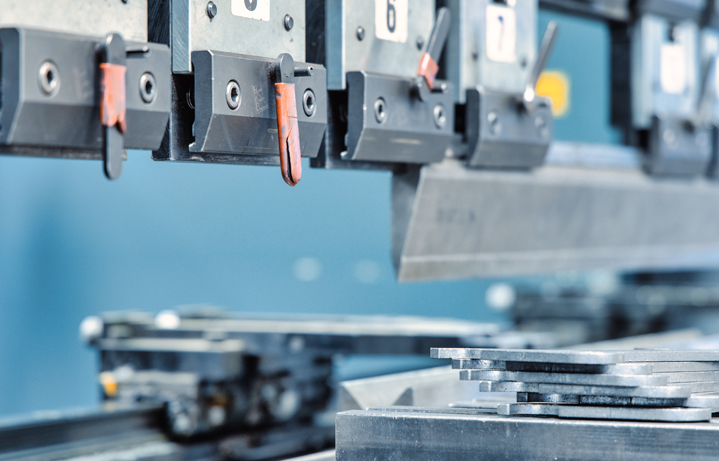

CNC Press Braking

Our DURMA press brake from the AD-SERVO series enables bending operations up to 3050 mm in length and press forces of up to 220 tons. The highly energy-efficient servo-hydraulic motors, combined with specially adapted control software, continuously optimize the valve block and pump pressure. This allows us to achieve energy savings of up to 72%, increase productivity by 60%, and reduce oil consumption by half compared to standard machines.

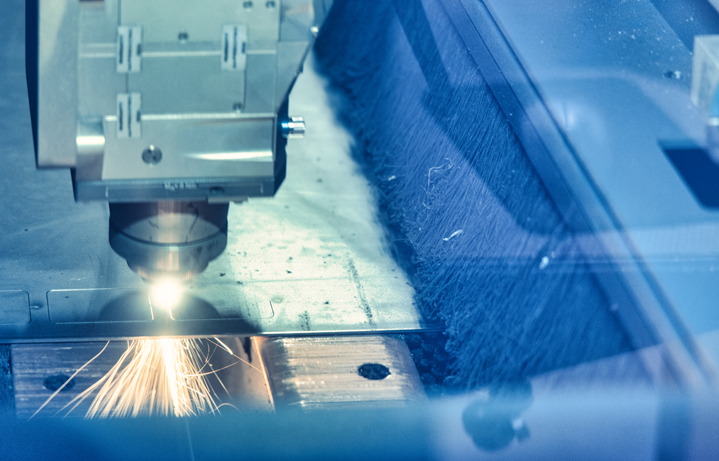

CNC Laser Cutting

CNC laser cutting enables highly precise contours, fine details, and virtually burr-free edges – even with complex geometries. The precisely guided laser beam ensures tight tolerances, minimal thermal distortion, and consistently high repeatability. This process is ideal for steel, stainless steel, and aluminum, providing an efficient, material-saving, and cost-effective solution for both individual parts and series production.

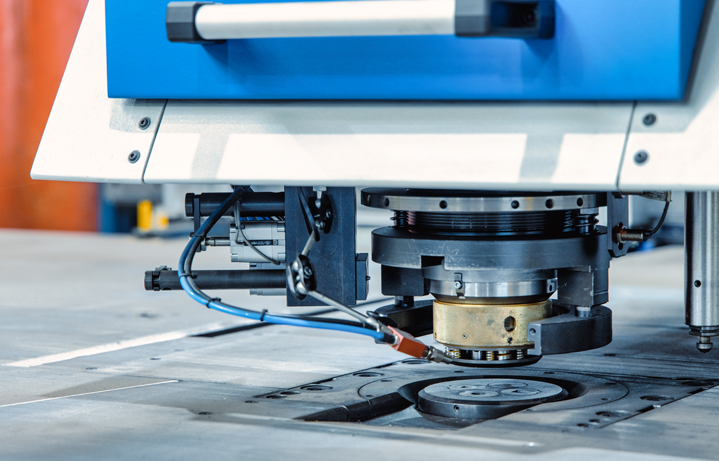

CNC Punching

CNC-controlled punching enables the fast and precise production of complex contours, cutouts, and outlines. The computer-controlled tool guidance ensures defined edges, high dimensional accuracy, and consistent repeatability – ideal for medium and large production runs. This process works with various materials and impresses with short cycle times, cost-effective manufacturing, and reliable quality even for demanding geometries.

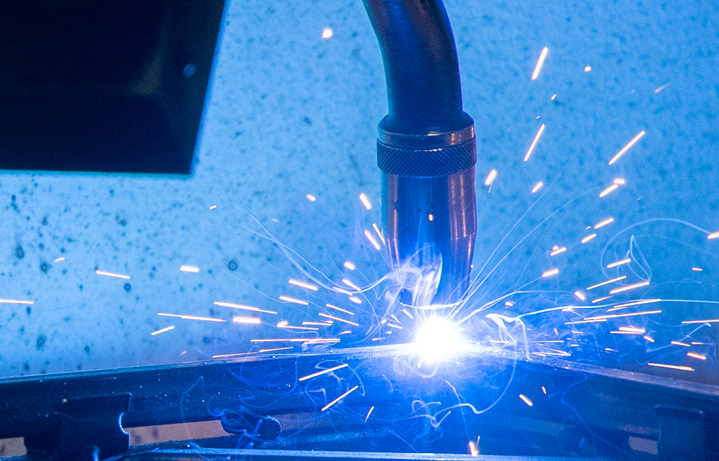

Welding

Our welding services include MIG, MAG, TIG as well as robotic, laser, and spot welding, providing optimal solutions for both individual parts and series production. MAG offers high speed for mass production, MIG impresses with versatile applications from steel to aluminum, and TIG delivers the highest precision for demanding welds. The CNC welding robot ensures reproducible results for large quantities, while laser welding achieves minimal thermal impact and maximum accuracy. Additionally, spot welding allows precise point connections for thin sheets and special alloys – always with documented testing and reliable quality.